When it comes to selecting a flat submersible cable for water pumps or industrial applications, there are several factors that one need to consider. However, most buyers being unaware of the same, often overlook some of the important factors that affect both performance and durability. We at Paraflex, being one of the leading flat submersible cable manufacturers, we not only deliver premium grade submersible cables. But we also share all the relevant information that makes it easier for one to invest in the right type of submersible cables. Here, in this blog, we are highlighting a few common mistakes that people make when buying flat submersible cables to help you avoid them and invest in the one with best quality for ensuring smoother operations.

Not inspecting quality of submersible cables

One of the most common mistakes when buying flat submersible cable is prioritizing cost over quality. One must understand that low quality cables may appear affordable initially. However, if we think of long term, they can cause huge equipment damage and may also increase the overall maintenance cost. That is why it is advised to buy from reputed flat submersible cable manufacturers who ensure that every submersible cable delivered by them is of optimum quality. They always use best quality material during manufacturing process and ensure that they test these cables through rigorous quality tests and standards.

Not verifying certification details

Are you also one of those people who often neglect checking the certifications achieved by submersible cable manufacturers? If yes, then you might end up buying cheap quality cables for submersible applications. It is strictly advised to look for manufacturers who adhere to international standards and certifications. Buying submersible cables from them helps ensure that you are buying certified cables that are tested for insulation resistance, water resistance, and mechanical strength, ensuring safety during prolonged submersion.

Overlooking the requirement of applications

Every water pump or industrial setup has specific requirements regarding voltage, current capacity, and environmental conditions. But being unaware of the same buyers often make the mistake of selecting a cable without considering these factors. This causes overheating, energy loss, and short circuits leading to further damage. It is advised to get complete information about the application for which you will use these cables and share those details with submersible manufacturers in India. It will help you invest in cables that match with the pump’s capacity, ensuring optimal performance.

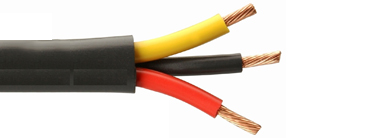

Neglecting features of flat submersible cables

The construction and material of a flat submersible cable significantly influence its features and longevity. It is one of the major reasons why it is advised to look for manufacturers who make use of high quality copper conductors for manufacturing these cables. Along with that, one must also check if these cables offer excellent insulation and flexible sheathing or not. They must also offer resistance to corrosion, cracks, and different water temperature. Always go for submersible cables that do not deteriorate when exposed to water for long time and are suitable to withstand harsh conditions.

Conclusion

If you are also planning to invest in flat submersible cables, ensure that you avoid all these mistakes. Be it ignoring quality or certifications, or overlooking features or application requirements, one must not make any of these mistakes if planning to invest in the best quality flat submersible cables. We at Paraflex, being a leading name among top flat submersible cable manufacturers, continue to set industry standards by offering durable and certified solutions for diverse applications. We are supporting our customers through our advanced quality submersible cables that are known for their lasting performance and durability.